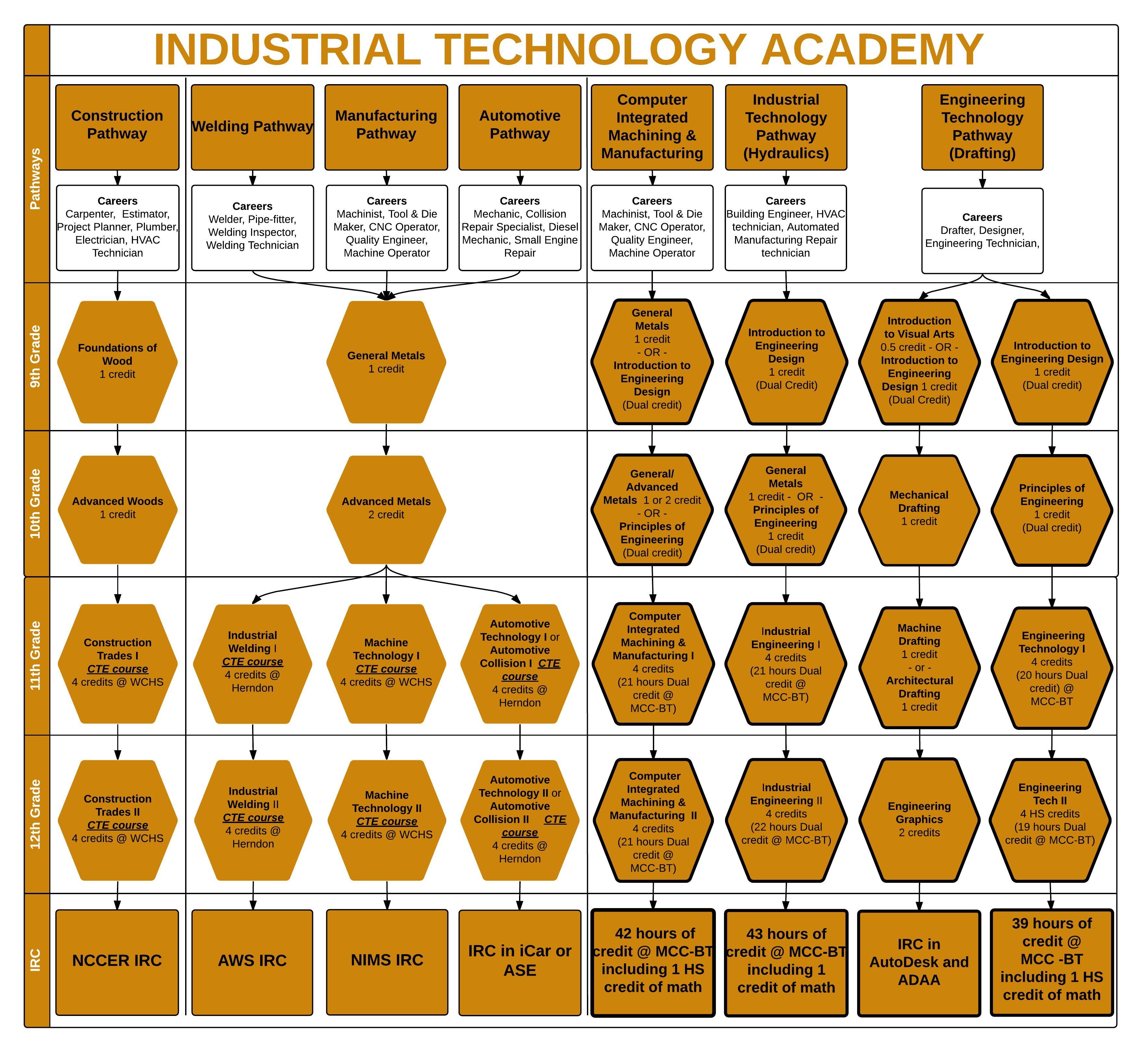

Industrial Tech Academy: Automotive Pathway

8131: General Metals (1 credit PAR, Gr. 9-12)

This fundamental course in metals is designed to give the student a basic understanding of tools, materials, and processes of the metal working industry. Problem solving experiences will be provided in the areas of sheet metal, wrought iron, welding, and machine shop work on the lathe, mill, shaper, drill press, and finishing areas. CNC machines will be introduced in this class. Required: Safety glasses

8133: Advanced Metals (2 credits/2 periods PAR, Gr. 10-12)

Prerequisite: General Metals

This advanced course in metals is designed to give the student a more in-depth understanding of tools, materials, and processes of the metal working industry. Problem solving experiences will be provided in the areas of the sheet metal, wrought iron, welding, and machine shop work on the lathe, mill, drill press, and finishing areas. The use of CNC machines will also be included in this course.

8523: Automotive Technology I (4 credit PAR, Gr. 11-12)

Prerequisite: Advanced Metals

This course is the first year of a two-year course intended to prepare students for entry-level jobs as technicians in maintenance and repair of passenger cars and light trucks. Students will have both classroom instruction and laboratory experiences with approximately 60% of the time devoted to classroom instruction. Proficiency in use of automotive service tools and instruction in the more advanced scientific and mechanical principles on the automobile will be an important part of the training experience.

8524: Automotive Technology II (4 credit PAR, Gr. 12)

Prerequisite: Automotive Technology I

This is the second year of a two-year course intended to prepare students for entry-level employment as technicians in the maintenance and repair of passenger cars and light trucks. Approximately 75% of the students' time will be spent repairing customer-owned vehicles with special emphasis in the use of test equipment for the purpose of diagnosing engine malfunction, steering-suspension and alignment adjustment, as well as air-conditioning repair. Classroom instruction will involve the introduction of technical information pertaining to the power plant, power train, automotive electronics, transmissions, and automotive air conditioning.

8503: Automotive Collison Repair I (4 credit PAR, Gr.11-12)

Prerequisite: Advanced Metals

This course is the first year of a two-year program designed to prepare students for entry-level jobs repairing and refinishing collision damaged vehicles. Employment opportunities exist in automotive dealerships, independent repair shops, specialty shops or fleet operations. Emphasis is placed on classroom instruction during the first year of the program while students work toward industry-recognized certifications from the Inter-Industry on Auto Collision Repair (I-CAR), Pittsburg Paint and Glass (PPG), and Audatex Estimating System (ADP). Lab experiences develop personal pride and craftsmanship using hand tools, power tools, welding and refinishing equipment.

8502: Automotive Collison Repair II (4 credits PAR, Gr. 12)

Prerequisite: Automotive Collison Repair I

This course is the second year of a two-year program designed to further develop the skills needed for entry-level or advanced positions in the automotive collision industry. Employment opportunities demand trained technicians who can use the changing technology in the auto collision field. Students will spend the majority of their time in the lab mastering the technical skills necessary to repair customer-owned, late- model vehicles with collision damage.