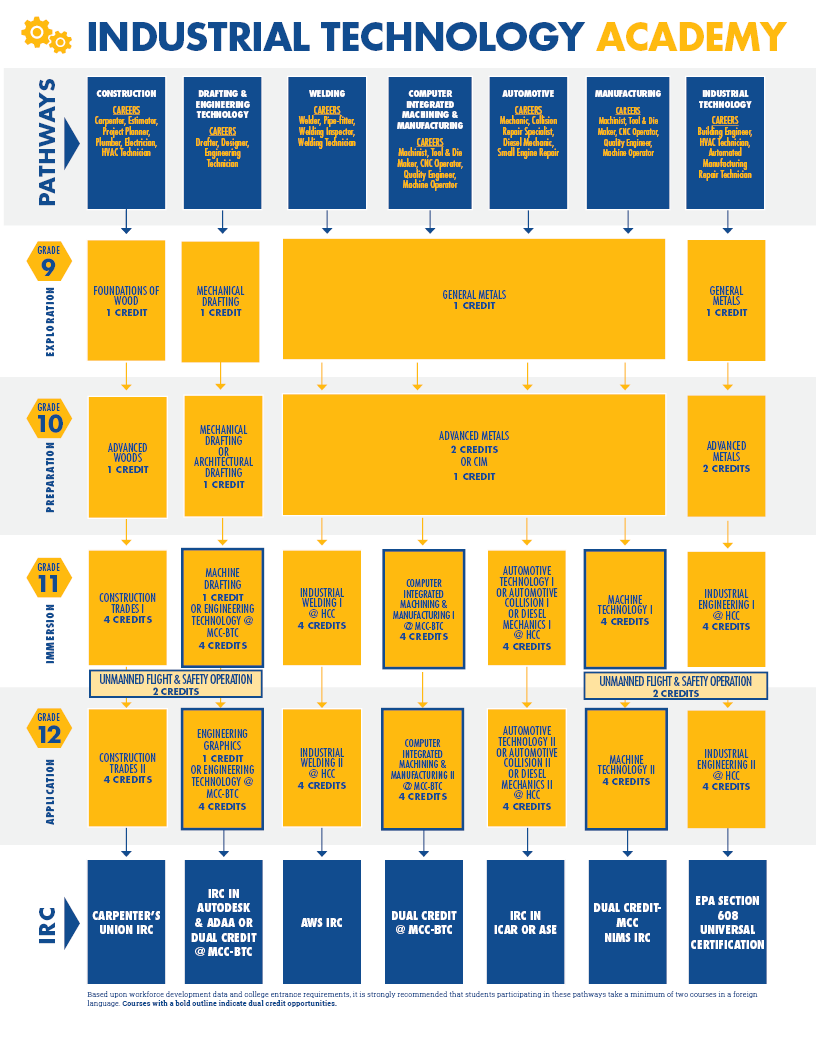

Industrial Technology Academy

The Academies of the ISD

- Freshman Academy

- Arts and Education Academy

- Business Academy

- Industrial Technology Academy

- Construction Pathway

- Drafting Pathway

- Welding Pathway

- Manufacturing Pathway

- Automotive Pathway

- Computer Integrated Machining and Manufacturing Pathway

- Industrial Technology Pathway (Hydraulics)

- Engineering Technology Pathway

- Public Services Academy

- STEM Academy

8133: Advanced Metals (2 credits PAR, Gr. 10-12)

Prerequisite: General Metals

This advanced course in metals is designed to give students a more in-depth understanding of tools, materials, and processes of the metal working industry. Problem solving experiences will be provided in the areas of sheet metal, wrought iron, welding, and machine shop work on the lathe, mill, drill press, and finishing areas. The use of CNC machines will also be included in this course.

8118: Advanced Woods (2 credits PAR, Gr. 10-12)

Prerequisite: Foundations of Wood Technology

This advanced course will reinforce students’ skills and knowledge related to carpentry and cabinetmaking. Topics covered in the course include: care and safe usage of equipment and machines; materials; fasteners; hand and power tools; and fabrication based on blueprints. This course gives students additional skills and knowledge typically required for apprentice carpenters.

8105: Architectural Drafting (1 credit PAR, Gr. 10-12)

Prerequisite: Introduction to Engineering Design or Introduction to Visual Arts

This course in drafting deals with the principals involved in site selection, room planning, exterior styling, designing structural elements of house dwellings, and computer graphics as it relates to architectural drawing. Students will be introduced to various construction methods, building materials, and terminology used in the architectural fields. Preparation of a complete set of plans and specifications for a house of traditional and/or contemporary design will be required in a CADD environment

8503: Automotive Collision Repair I - 4 credits (3 credits PAR and 1 credit SCI, Gr. 11-12)

Prerequisite: Advanced Metals

This course is the first year of a two-year program at Herndon Career Center designed to prepare students for entry-level jobs repairing and refinishing collision damaged vehicles. Employment opportunities exist in automotive dealerships, independent repair shops, specialty shops or fleet operations. Emphasis is placed on classroom instruction during the first year of the program while students work toward industry-recognized certifications from the Inter-Industry on Auto Collision Repair (I-CAR), Pittsburg Paint and Glass (PPG), and Audatex Estimating System (ADP). Lab experiences develop personal pride and craftsmanship using hand tools, power tools, welding and refinishing equipment.

8502: Automotive Collision Repair II - 4 credits (3 credits PAR and 1 credit SCI, Gr. 12)

Prerequisite: Automotive Collision Repair I

This course is the second year of a two-year program at Herndon Career Center designed to further develop the skills needed for entry-level or advanced positions in the automotive collision industry. Employment opportunities demand trained technicians who can use the changing technology in the auto collision field. Students will spend the majority of their time in the lab mastering the technical skills necessary to repair customer-owned, late-model vehicles with collision damage.

8523: Automotive Technology I - 4 credits (3 credits PAR and 1 credit SCI, Gr. 11-12)

Prerequisite: Advanced Metals

This course is the first year of a two-year program at Herndon Career Center intended to prepare students for entry-level jobs as technicians in maintenance and repair of passenger cars and light trucks. Students will have both classroom instruction and laboratory experiences with approximately 60% of the time devoted to classroom instruction. Proficiency in use of automotive service tools and instruction in the more advanced scientific and mechanical principles on the automobile will be an important part of the training experience.

8524: Automotive Technology II - 4 credits (3 credits PAR and 1 credit SCI, Gr. 12)

Prerequisite: Automotive Technology I

This is the second year of a two-year program at Herndon Career Center intended to prepare students for entry-level employment as technicians in the maintenance and repair of passenger cars and light trucks. Approximately 75% of the time will be spent repairing customer-owned vehicles with special emphasis in the use of test equipment for the purpose of diagnosing engine malfunction, steering-suspension and alignment adjustment, as well as air-conditioning repair. Classroom instruction will involve the introduction of technical information pertaining to the power plant, powertrain, automotive electronics, transmissions, and automotive air conditioning.

8119: Computer Integrated Manufacturing (1 credit PAR, Gr. 10-12, weighted)

Prerequisite: Introduction to Engineering Design

Manufactured items are part of everyday life, yet most students have not been introduced to the high-tech, innovative nature of modern manufacturing. This course illuminates the opportunities related to understanding manufacturing. At the same time, it teaches students about manufacturing processes, product design, robotics, and automation. Students can earn a virtual manufacturing badge recognized by the National Manufacturing Badge System.

8802: Computer Integrated Machining and Manufacturing I (4 credits PAR, Gr. 11-12, weighted) College Credit Available

Prerequisite: Advanced Metals or Introduction to Engineering Design

This course at Metropolitan Community College - Business and Technology Campus is designed to introduce the student to the manufacturing environment, requirements, and career opportunities of major technologies in the industry. The course will cover the history, setting of manufacturing and industry, safety, drawing, measurement and layout, and an introduction to basic shop equipment.

8804: Computer Integrated Machining & Manufacturing II (4 credits PAR, Gr. 12, weighted) College Credit Available

Prerequisite: Computer Integrated Machining & Manufacturing I

This course at Metropolitan Community College - Business and Technology Campus covers the safe use of basic shop power equipment and hand tools. Students will learn precision measurement methods. The course is designed for students in engineering disciplines and serves as a prerequisite for supervised use of the Engineering Student Machine Shop.

8250: Construction Trades I (4 credits PAR, Gr. 11-12)

Prerequisite: Advanced Woods

This half day course provides students the opportunity to extend their skills and knowledge related to residential and commercial carpentry. Topics covered in the course include: installation and trim of windows and doors; installation and repair of gypsum wallboard; advanced site layout; exterior and interior finish work; and thermal and moisture protection. This course gives students a substantial skill and knowledge foundation typically required for apprentice carpenters.

8252: Construction Trades II (4 credits PAR, Gr. 12)

Prerequisite: Construction Trades I

This second level, half day course provides students additional opportunities to refine their skills and knowledge related to residential and commercial carpentry. Topics covered in the course include: installation and trim of windows and doors; installation and repair of gypsum wallboard; advanced site layout; exterior and interior finish work; and thermal and moisture protection.This course gives students a substantial skill and knowledge foundation typically required for apprentice carpenters.

5126: Design Thinking (1-2 credits ELE, Gr. 12)

Prerequisite: Approved Capstone Project

This capstone is a project that allows students to learn about themselves by moving an idea or dream toward a topic of interest, specialization, community need, or career choice. As part of this course, all students must complete a capstone experience which may include, but is not limited to: senior project, virtual enterprise, internship, externship, work-based learning, service learning, community service, etc.

8121: Engineering Graphics (1 credit PAR, Gr. 12, weighted)

Prerequisite: Machine Drafting

This is an advanced course in technical drafting through mechanical processes with a CADD environment. Course topics will include sketching, projection, drawing layout, drafting standards and conventions, dimensioning, sectioning and auxiliaries. Foundations for CADD consist of file management, drawing commands, editing commands, layering conventions, blocks, dimensioning and plotting.

8806: Engineering Technology I (4 credits PAR, Gr. 11-12, weighted) College Credit Available

Prerequisite: Mechanical Drafting

This course at Metropolitan Community College - Business and Technology Campus provides an introduction to engineering communications and basic computer aided drafting/design (CADD). Emphasis will be placed on technical sketching, orthographic projection, drawing layout, drafting and CADD standards and conventions, dimensioning, sectioning, annotation, and basic design principles. Students will develop a foundation for computer aided drafting/design including file management, basic drawing and editing commands, layering, blocks and wblocks, dimensioning, polylines, hatching, and plotting.

8808: Engineering Technology II (4 credits PAR, Gr. 12, weighted) College Credit Available

Prerequisite: Engineering Technology I

This course at Metropolitan Community College - Business and Technology Campus focuses on advanced engineering communications and basic computer aided drafting/design (CADD). Additional emphasis will be placed on technical sketching, orthographic projection, drawing layout, drafting and CADD standards and conventions, dimensioning, sectioning, annotation, and basic design principles. Students will further develop their foundation for computer aided drafting/design including file management, basic drawing and editing commands, layering, blocks and wblocks, dimensioning, polylines, hatching, and plotting.

8109: Foundations of Wood Technology (1 credit PAR, Gr. 9-11)

This fundamental course stresses the development of tools, machine safety, and skills. Students will gain knowledge in the safe use of hand and power tools, machines, career exploration, project planning, problem-solving, and applied math and science. Students will have an understanding for the awareness of industry employment expectations, job outlooks, and educational requirements. This is a project-oriented course in wood working where students will be assigned to construct medium sized project. Students will be required to have safety glasses and 3-ring binder.

8131: General Metals (1 credit PAR, Gr. 9-11)

This fundamental course in metals is designed to give students a basic understanding of tools, materials, and processes of the metal working industry. Problem solving experiences will be provided in the areas of sheet metal, wrought iron, welding, and machine shop work on the lathe, mill, shaper, drill press, and finishing areas. CNC machines will be introduced in this class. Safety glasses are required.

8810: Industrial Engineering I (4 credits PAR, Gr. 11-12, weighted) College Credit Available

Prerequisite: Principles of Engineering or General Metals

This course at Metropolitan Community College - Business and Technology Campus is designed to present the fundamentals of the care and maintenance on a wide range of industrial equipment, including chain and gear drives, couplings, and fluid power equipment. Additionally, lubricants and lubrication of industrial equipment will be covered, as well as, the replacement of seals and bearings. Correct application and selection of hand and power tools will be taught. Basic motor alignment, including laser alignment, will be introduced.

8811: Industrial Engineering II (4 credits PAR, Gr. 12, weighted) College Credit Available

Prerequisite: Industrial Engineering I

This second level course at Metropolitan Community College - Business and Technology Campus is designed to further explore the care and maintenance on a wide range of industrial equipment, including chain and gear drives, couplings, and fluid power equipment. Additionally, lubricants and lubrication of industrial equipment will be covered, as well as, the replacement of seals and bearings. Correct application and selection of hand and power tools will be taught. Basic motor alignment, including laser alignment, will be introduced.

8535: Industrial Welding I - 4 credits (3 credits PAR and 1 credit MTH or SCI, Gr. 11-12)

Prerequisite: Advanced Metals

This course at Herndon Career Center is the first year of a two-year program that prepares students to meet the American Welding Society's entry-level employment requirements or pursue post-secondary training. Laboratory work includes basic flame cutting, oxy-fuel welding and shielded metal arc welding of mild steels. Classroom instruction covers welding theory, terminology, techniques, measuring and mathematics. Safety, work ethic and employability skills are emphasized at all times.

8536: Industrial Welding II - 4 credits (3 credits PAR and 1 credit MTH or SCI, Gr. 12)

Prerequisite: Industrial Welding I

This course at Herndon Career Center is the second year of a two-year program that prepares students to meet the American Welding Society's entry-level employment requirements or pursue post-secondary training. Major units of study include advanced shielded metal arc welding (structural and pipe), plus gas metal arc welding, gas tungsten arc welding and plasma arc cutting on carbon, stainless steel and aluminum. Classroom instruction covers advanced welding theory, blueprint reading, and layout and fit-up. Safety, work ethic, employability skills, quality of work and pride in workmanship are emphasized at all times.

8107: Machine Drafting (1 credit PAR, Gr. 11-12)

Prerequisite: Mechanical Drafting or Architectural Drafting

This advanced course in drafting, emphasizes the techniques and skills gained through basic drawing courses as applied to industrial parts. The course is organized in a way to allow creativity in design while still learning drafting standards and technical information in a computer graphics environment.

8135: Machine Technology I (4 credits PAR, Gr. 11-12)

Prerequisite: Advanced Metals

The course in machine technology prepares students for employment in a machine shop or related field. Each student will have the opportunity to learn how to properly operate and use the basic machines and hand tools located in most shops. The use of CNC machines will also be used to produce projects related to the industry. The correct handling and reading of precision measuring tools will be included in the course. Basic shop math and blue-print interpretation will be taught.

8137: Machine Technology II (4 credits PAR, Gr. 12)

Prerequisite: Machine Technology I

This advanced course in machine technology emphasizes the construction of special tools, jigs, fixtures and dyes. Each student will be able to gain additional knowledge and skills in using hand tools, precision measuring tools, and also operating the power machines. Individual study will be designed to coincide with the special tool a student selects to construct his/her major project. Students will be taught how to interpret working drawings and construct projects to meet drawing specifications.

8103: Mechanical Drafting (1 credit PAR, Gr. 9-12)

This is an introduction to mechanical drafting. The course will emphasize the fundamentals of drafting with paper and pencil. Course topics will include: sketching, projection, drawing layout, drafting standards, conventions, dimensioning, sectioning and basic design principles.

8101: Principles of Engineering (1 credit PAR, Gr. 10-12, weighted)

Prerequisite: Introduction to Engineering Design

Recommended Concurrent Course: Algebra II

This course explores the wide variety of careers in engineering, technology systems, and manufacturing processes. Using activities, projects and problems, students will learn first-hand how engineers and technicians use math, science and technology in an engineering problem-solving process to benefit people. PLTW is a nationally recognized engineering curriculum being offered through the Independence School District. For more information regarding PLTW go to www.pltw.org.

8826: Unmanned Flight Safety & Operation (2 credits PAR, Gr. 12, weighted) College Credit Available

Prerequisite: Aerospace Engineering

The drone market is exploding. This course will provide valuable learning experiences for anyone entering the utilities field, aviation, marketing, building maintenance, shipping, and many more careers. Course curriculum will be through the Unmanned Safety Institute, a premier instructional group for unmanned flight. This course follows Project Lead the Way's Aerospace Engineering class and provides the opportunity to earn certification to fly a drone.