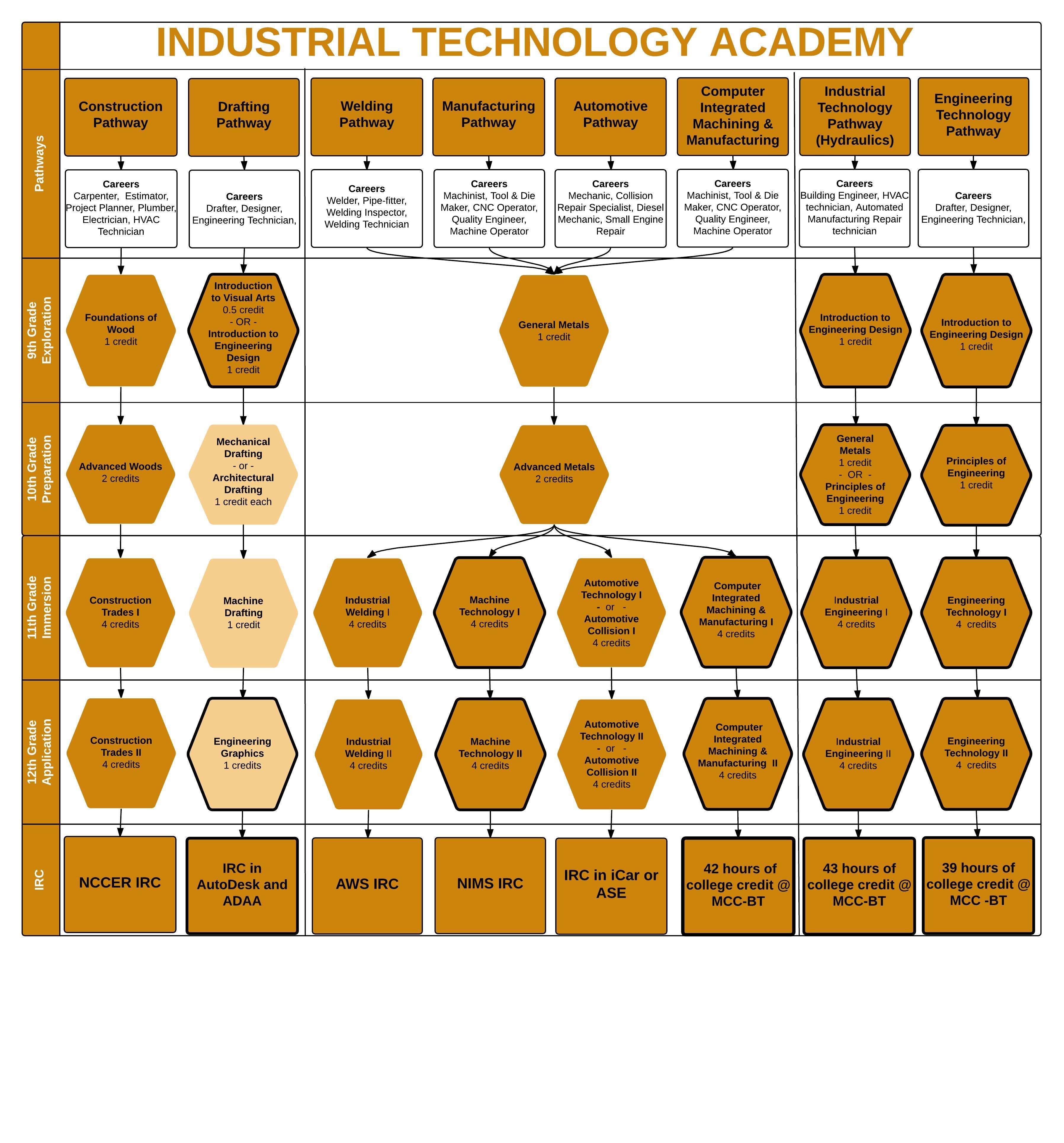

Industrial Tech Academy: Welding Pathway

8131: General Metals (1 credit PAR, Gr. 9-11)

This fundamental course in metals is designed to give students a basic understanding of tools, materials, and processes of the metal working industry. Problem solving experiences will be provided in the areas of sheet metal, wrought iron, welding, and machine shop work on the lathe, mill, shaper, drill press, and finishing areas. CNC machines will be introduced in this class. Safety glasses are required.

8133: Advanced Metals (2 credits PAR, Gr. 10-12)

Prerequisite: General Metals

This advanced course in metals is designed to give students a more in-depth understanding of tools, materials, and processes of the metal working industry. Problem solving experiences will be provided in the areas of sheet metal, wrought iron, welding, and machine shop work on the lathe, mill, drill press, and finishing areas. The use of CNC machines will also be included in this course.

8535: Industrial Welding I - 4 credits (3 credits PAR and 1 credit MTH or SCI, Gr. 11-12)

Prerequisite: Advanced Metals

This course at Herndon Career Center is the first year of a two-year program that prepares students to meet the American Welding Society's entry-level employment requirements or pursue post-secondary training. Laboratory work includes basic flame cutting, oxy-fuel welding and shielded metal arc welding of mild steels. Classroom instruction covers welding theory, terminology, techniques, measuring and mathematics. Safety, work ethic and employability skills are emphasized at all times.

8536: Industrial Welding II - 4 credits (3 credits PAR and 1 credit MTH or SCI, Gr. 12)

Prerequisite: Industrial Welding I

This course at Herndon Career Center is the second year of a two-year program that prepares students to meet the American Welding Society's entry-level employment requirements or pursue post-secondary training. Major units of study include advanced shielded metal arc welding (structural and pipe), plus gas metal arc welding, gas tungsten arc welding and plasma arc cutting on carbon, stainless steel and aluminum. Classroom instruction covers advanced welding theory, blueprint reading, and layout and fit-up. Safety, work ethic, employability skills, quality of work and pride in workmanship are emphasized at all times.